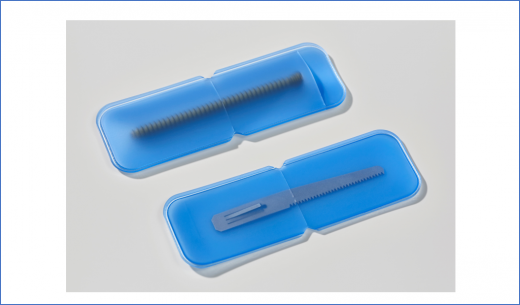

Proud winner of the Swiss Packaging Award 2025: MED-Pack eco

Special thanks go to Georg Oesterreicher and Sara Schnurrenberger, who developed this innovative packaging solution.

MED-Pack eco – Sustainable and safe

MED-Pack eco combines ecological responsibility with high functionality. The packaging is made of monomaterials with recycled content, uses less material than conventional solutions and reduces packaging volume thanks to its compact design. The integrated fixation protects the contents optimally, while the 'no-touch' design enables safe and hygienic removal in the operating theatre. MED-Pack eco is pre-validated for long shelf life and can be processed efficiently and automatically – without any additional development or tooling costs.

What is the SVI Swiss Packaging Award?

The Swiss Packaging Award is presented annually by the Swiss Packaging Institute (SVI) and honours the best and most innovative packaging solutions in Switzerland. An independent jury of experts evaluates the submissions according to criteria such as innovation, sustainability and functionality.

Successful final apprenticeship examination

During his apprenticeship at MEDIPACK AG, he impressed us with his commitment, curiosity and specialist knowledge.

Proof of his creativity and skills was the original gift he received on the occasion of our boss's birthday: together with his trainer, he developed a tea set, cleverly packaged in a high-quality blister pack of his own design.

A big thank you to our apprentice for his fantastic efforts. We would also like to thank his dedicated trainer and the whole team for their valuable support throughout his apprenticeship. We are proud of this teamwork!

We wish Colin all the best for the future and are delighted that he will continue to support us with the specialist knowledge he has acquired.

Service Aniversary

At a cosy dinner, we celebrated the employees who celebrated their service anniversary in 2024 - with fine food, good conversation and many wonderful moments. Together, our jubilarians have an impressive 120 years of Medipack experience - that's really something special!

It was great to see how much commitment, knowledge and passion has come together over all these years. Evenings like this show how strong our team is - and how important each individual is for our shared journey.

A big thank you to our jubilarians!

Translated with DeepL.com (free version)

MEDICAL DAY 2025

A review of the SHN from 11.04.25

Read the article on www.shn.ch

How a sandwich film saves CO₂ - a tour of Medipack AG

Last Wednesday was all about sustainable medical technology. The Medical Day organised by the Industrie- und Technozentrum Schaffhausen ITS offered exciting keynote speeches and live demonstrations for companies in the sector. The morning began with a tour of the Schaffhausen-based company Medipack, which surprised visitors with innovative packaging solutions.

The Mühlental business centre, where the company is based, looks back on a long industrial history. Today, the entire site belongs to Medipack AG, which has grown steadily since it was founded by Aldo Artusi in 1977 and now employs over 240 people. The company develops and produces packaging used for sterile implants and surgical instruments - an area in which absolute reliability counts.

The sustainable use of materials and the consistent further development of processes make Medipack a leading company in the production of environmentally friendly packaging for medical technology. A look behind the scenes at the company showed how innovation and sustainability are combined. Felix Neidhart, Head of Sales, guided the guests through the production facilities and gave an insight into the processes.

Customised packaging solutions

The tour took us through the various areas of the factory, which Medipack has been continuously expanding for decades. The company offers a wide range of packaging solutions: from development and blister production in a clean room to sealing technology and comprehensive packaging services. "Thanks to our own development department, our own mould construction and decades of experience, we can offer our customers professional packaging solutions that are precisely tailored to their individual requirements within a very short space of time," explains Neidhart.

"Thanks to our own development department, in-house mould construction and decades of experience, we can offer our customers professional packaging solutions that are precisely tailored to their individual requirements in the shortest possible time" - Felix Neidhart, Head of Sales at Medipack AG

In the machine room, modern CNC milling machines produce precisely customised tools for the packaging solutions. The guests were also given an insight into the clean rooms, where employees in light blue full-body suits count, clean and pack the products under strictly controlled conditions.

What makes a film sustainable?

During the tour, particular attention was paid to the production of the innovative thermo film used for packaging. In the in-house film extrusion process, plastic granules are dried, melted and extruded in several layers, i.e. pressed through a die to produce a film. The special thing about it? The centre layer of this thermal film consists entirely of recycled material, while the outer layers are made of new plastic - necessary for product safety and sealing.

The middle layer accounts for around 80 per cent of the film thickness. The granulate for the centre layer comes from internal production residues such as edge strips and punching grids, which are shredded, processed into flakes and reused - a closed loop. "This saves us around 1.5 tonnes of CO₂ per week," says Neidhart.

Medical technology and environmental protection

Reto Artusi, CEO of Medipack AG, explained how this significant milestone in in-house film extrusion came about in the subsequent presentation. Ten years ago, the topic of "sustainability" was not yet central, but Artusi was already bothered by the long transport routes: "This step was triggered when our Swiss supplier at the time announced that it was relocating its production to Portugal. Instead of relying on a new supplier, we asked ourselves: 'Can't we do it ourselves - precisely tailored to our niche market?"

A CO₂ balance sheet revealed that it was not electricity or gas, but the purchased thermal film and granulate that were responsible for around 70 per cent of emissions. This realisation was decisive for the development of the "WPG Eco-Friendly film", which Medipack claims is environmentally friendly. According to Artusi, the company demonstrates that sustainable processes can be reconciled with the high demands of medical technology. "This brings us closer to our joint climate target and makes an active contribution to environmental protection."

Two Experts - One System Solution

At this year's Pharmapack in Paris, we have the pleasure of being guests at the FischerSöhne AG stand. Together we will be presenting a comprehensive solution for packaging and sealing in the pharmaceutical industry.

Two experts, one perfect system solution

FischerSöhne AG from Muri is a leading supplier of plastic packaging. With its many years of experience in injection moulding and extrusion blow moulding, the company develops and produces high-quality tubs and nests that protect sensitive pharmaceutical products safely and efficiently.

As a specialist in heat-sealing machines and Tyvek® sealing lids, MEDIPACK AG ideally complements these competences. The collaboration results in a holistic solution:

TWO EXPERTS - ONE SYSTEM SOLUTION - FischerSöhne supplies the packaging and MEDIPACK provides the perfect seal.

Visit us in Paris! We look forward to exciting discussions.

Team Event

As part of the annual team event, our order management team visited the imposing Munot in Schaffhausen and was initiated into the secrets of the Munot by the Munot guardian.

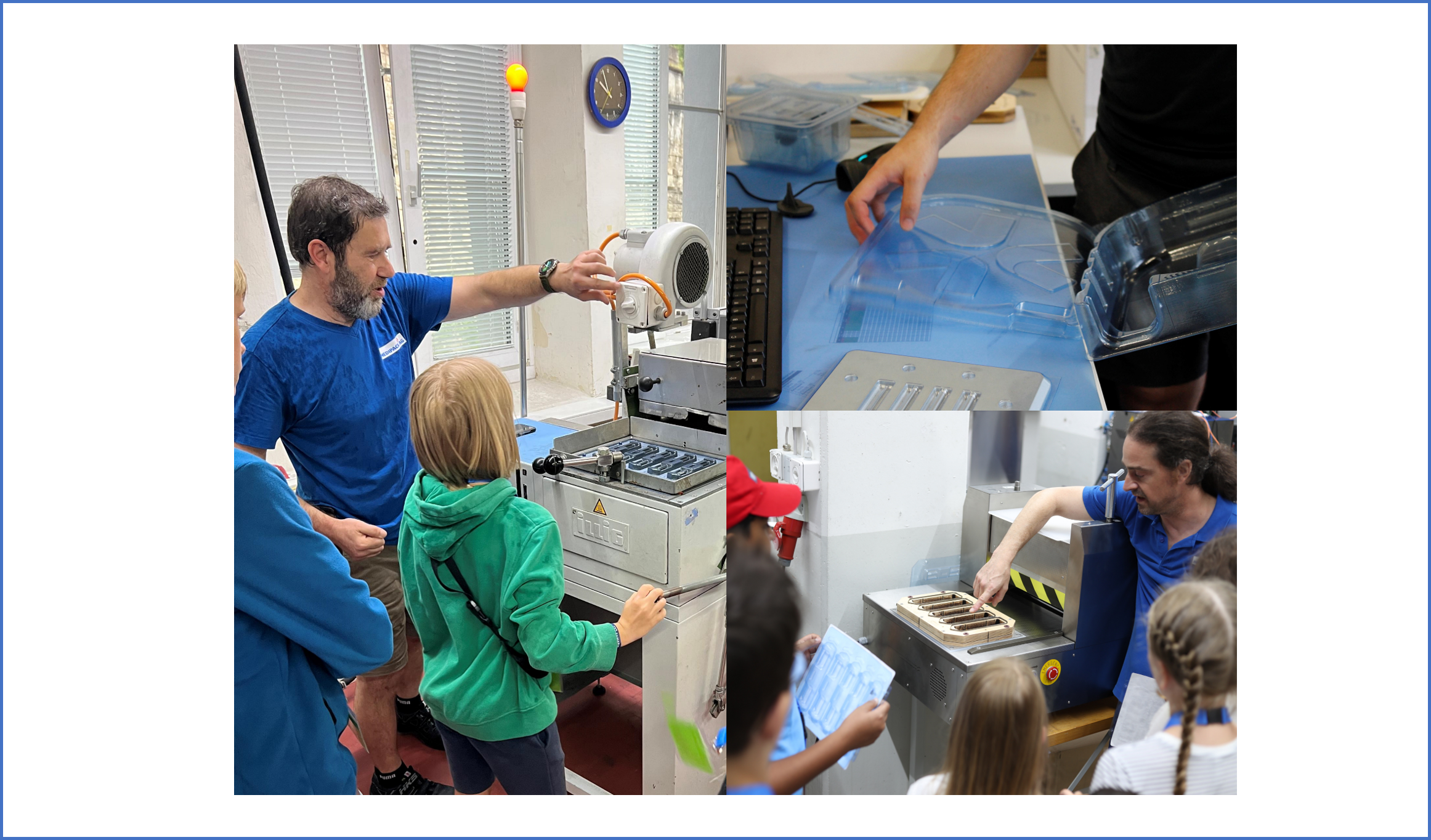

Medical technology up close: go tec foundation summer camp

As part of this year's summer camp, 27 young people and 4 accompanying adults visited our company and gained an insight into the processes of a medical company. In our development department, the participants learnt how a drawing is created using CAD. They were able to thermoform their own blisters on our sample thermoforming machine, which they then sealed with a Tyvek® sealing lid on our heat-sealing machine.

We are delighted to be able to offer young people an insight into technical professions and thus help to combat the shortage of skilled labour. By giving them hands-on experience and fascinating insights into the world of technology, we want to spark their interest in these professions and encourage them to pursue a career in this field. We are convinced that initiatives such as these play a key role in nurturing the skilled workers of tomorrow and strengthening the region in the longterm.

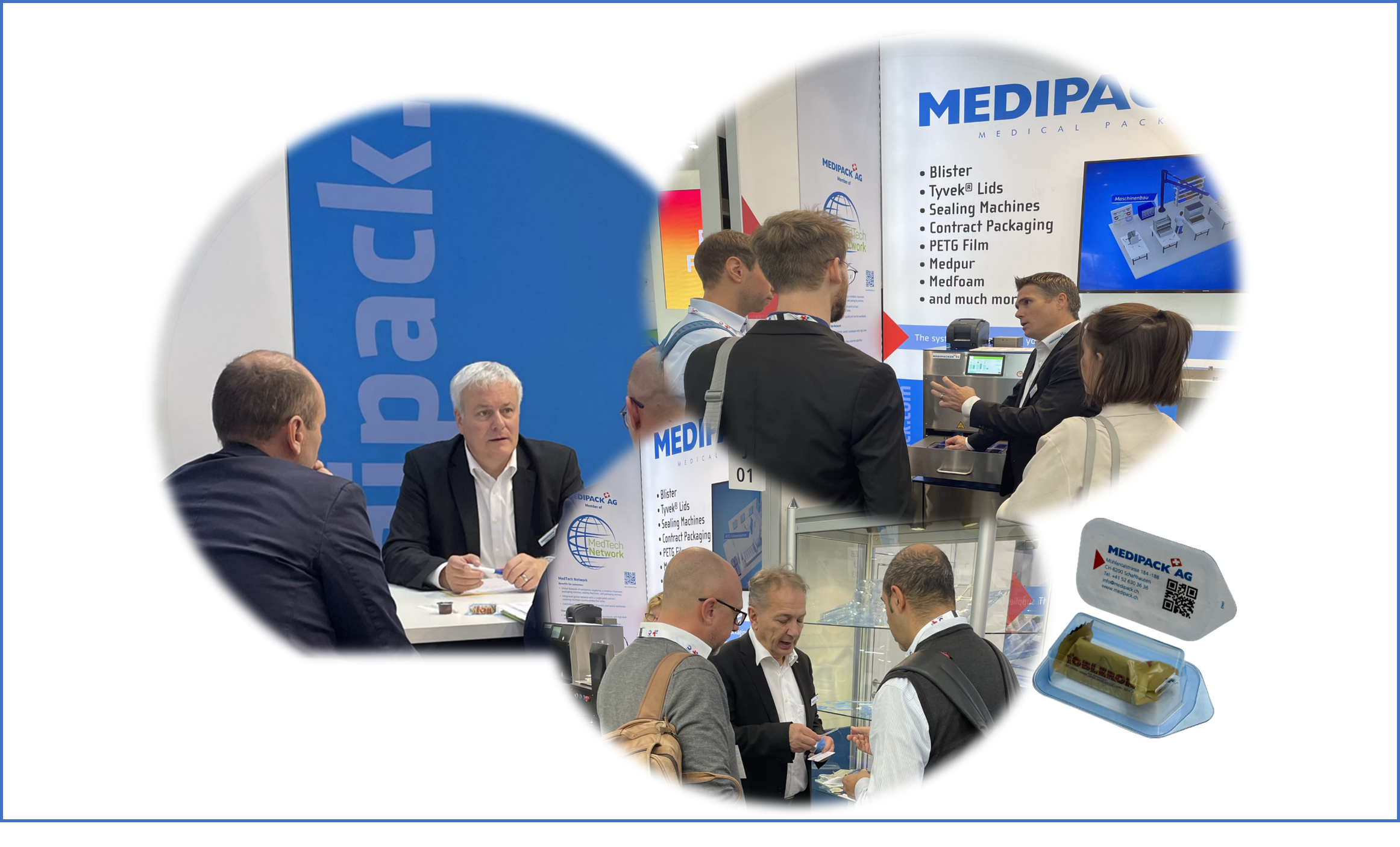

MedtecLIVE, Stuttgart

MedtecLIVE in Stuttgart was a complete success.

We were able to hold many exciting discussions with customers and around 300 footballs were handed in at the scavenger hunt organized with six other exhibitors. ⚽

And we saved the best for last: the Swiss national team put in a solid performance and deserved to reach the quarter-finals.

MedtecLIVE with a scavenger hunt

During MedtecLIVE, Stuttgart will not only be a center for innovation and networking, but also a hotspot for football fans. The European Football Championship will take place at the same time as the trade fair!

To celebrate this special event in style, seven exhibitors have come up with something very special: a scavenger hunt along the entire value chain.

From component production, cleaning, labeling and passivation to packaging, you can visit the various suppliers.

Here's how it works:

1. pick up your stamp card from one of the participating exhibitors.

2. visit all seven exhibitors and have your card stamped at each

of them.

3. when your card is complete, exchange it for a brand new

football! ⚽️

Take advantage of this opportunity and come and visit us. We will be happy to show you our product range and advise you in a personal meeting. Let's celebrate the trade fair season and the football championship together.

See you at our stand no. 1-502 and of course very important:

"Hopp Schweiz"

MEDIPACK takes part in the Karl Storz soccer tournament

Instead of an entry fee, participating companies can donate an amount to a good cause. This year, the proceeds will go to the Tuttlingen Women's Shelter.

MEDIPACK took part with a football team and finished 4th out of a total of 21 teams. Of course, this brilliant result had to be celebrated. CONGRATULATIONS !

Easter 2024

Automatic Cutting Machine ZSM 40AL

Find out more about our interesting ZSM 40AL cutting machine.

Annual Dinner 2023

A Croatian folklore dance group led by one of our employees performed as a surprise guest. Under guidance, a few brave souls also dared to take their first dance steps.

Succesful COMPAMED 2023

Four busy, exciting and successful trade fair days are over. Our team had many interesting discussions and, of course, our give-away was once again a big hit. COMPAMED is a highlight for us every year.

Barbecue

Photovoltaic System

It is planned to install further systems on our roof surfaces.

New Image Film

Take a look - we are sure you will like it as much as we do.

Successful Completion of Apprenticeship as a Polymechanic EFZ

MedtecLIVE, Nuremberg

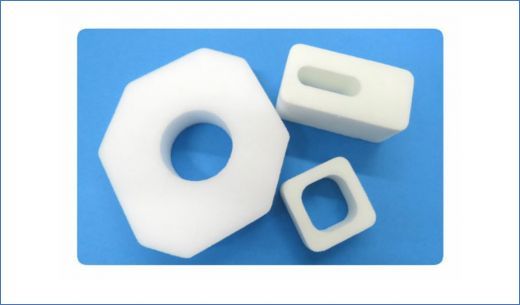

We are particularly proud of the presentation of our new MEDPUR product range. Our dedicated team has worked hard to develop innovative solutions that meet the needs of our customers. The positive feedback and enthusiastic reactions to our MEDPUR products have shown us that we are on the right track.

Stars in Town, Schaffhausen

MEDIPACK AG enables its employees to buy tickets at half price. It is a big hello every year when "Medipäckler" meet on the Herrenacker, move to the beat of the music, enjoy a beer or a fine drink together and just have a good time. We are already looking forward to the start of the festival in August.

Paper Consumption

Christmas Present

Las Vegas meets MEDIPACK

"Las Vegas meets Medipack" was the motto. Animated by experienced croupiers, roulette, blackjack and poker were played at various tables. If we had played for real money, many a millionaire would have gone home.

Many thanks to Swisscom for the generous support and assistance in the organization and to the company Events 4 Rent for the sympathetic and competent casino implementation.

MEDIPACK Goes On Tour

Christmas

Compamed 2022

Blister Configurator

It's easy - with our blister configurator, a solution is quickly and easily suggested to you in a 3D visualisation.

Our team will be happy to advise you personally. Fill in all the necessary details and your enquiry will automatically be sent to our sales team. Based on your information, we will be happy to submit a suitable packaging proposal.

Successful Apprenticeship

We congratulate him on his successful graduation and wish him all the best for the future.

* Ranking grade from 5.3

MedtecLive 2022, Stuttgart

Blister Finder

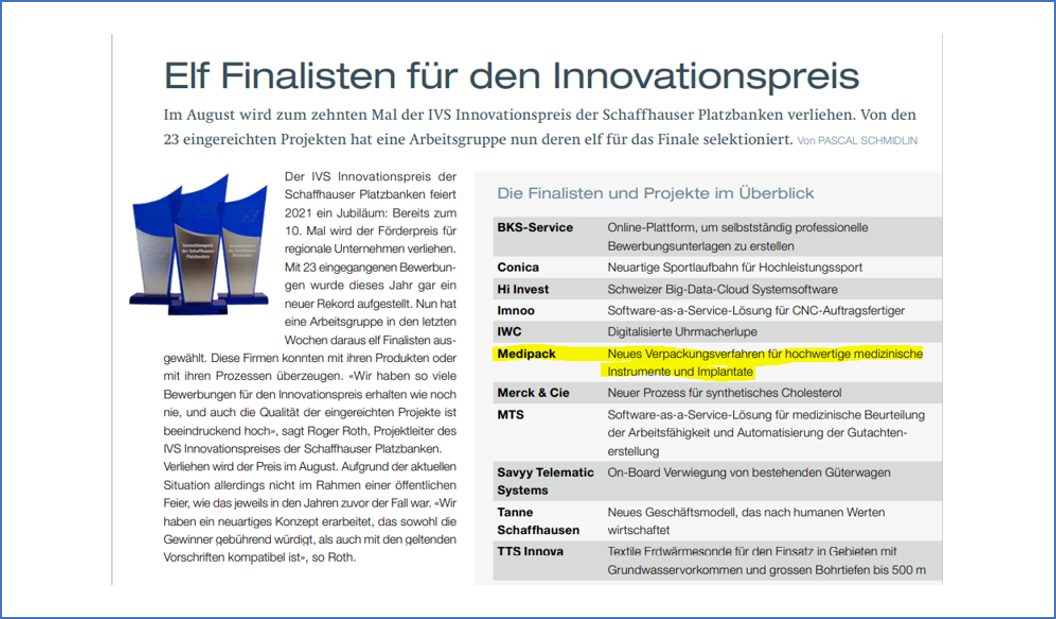

We are in!

We applied with the project "New packaging process for high-quality medical instruments and implants".

What is it about?

We have developed a process to produce medical packaging for sharp-edged implants and instruments with the material MEDPUR. This tested material is particularly suitable because there is no abrasion from friction. The product or instruments are not contaminated and remain sterile.

We use this material to produce MEDPURPOUCHES and FIX TRAYs.

Courageous Step for the Future

"Going against the flow" – we have taken this expression to heart and – contrary to what normally happens in a crisis – we are investing in the construction of a new cleanroom.

What prompted us to implement such a project during these uncertain and difficult times?

The increased demand for medicinal packaging requires a larger production area. In addition, our first cleanroom has reached the end of its lifetime and needs to be replaced.

We care about the Future

We go into more detail in our document Environment & Energy.

MEDIPACK on a Trip

(Images submitted by employees - more to follow)

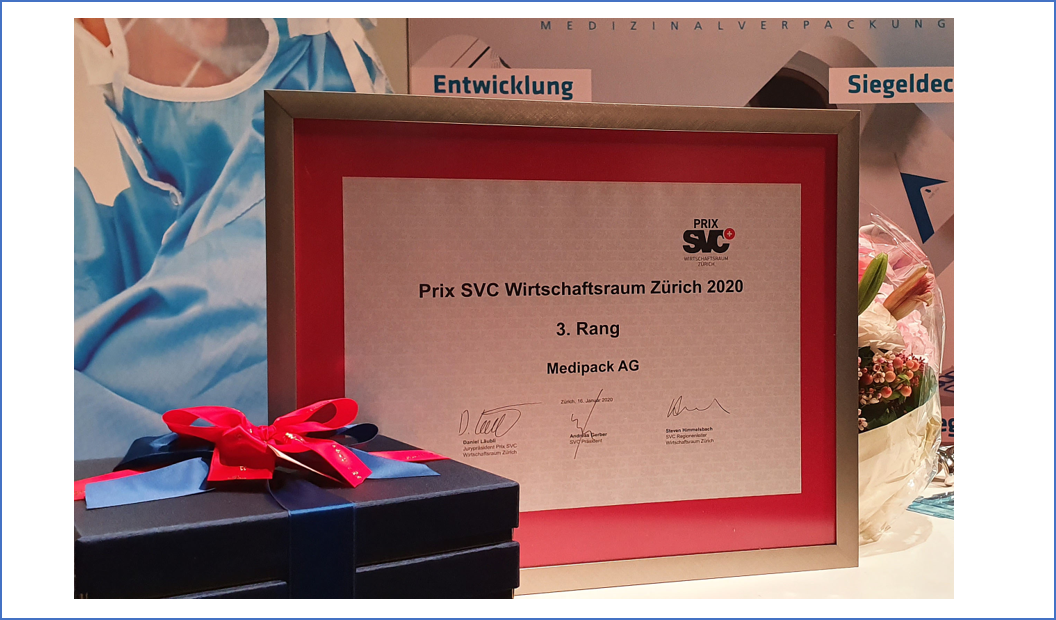

Prix SVC

The Prix SVC for the Zurich Economic Area (Prix SVC Wirtschaftsraum Zürich) is awarded to leading SMEs, which impress with their innovative products and services, their corporate culture, the quality of their employees and management, and their enduring record of success.

A jury comprised of seven experts chose six finalists from roughly 100 companies from the Zurich economic area.

An audience of around 1800 eagerly awaited the announcement of the winners along with the nominees. The radio and television personality Nik Hartmann expertly moderated the programme, keeping everyone captivated until the announcements were made. For the delegation from Medipack the evening was an unforgettable experience. The award fills us with pride and is a confirmation of our many years of high quality work.

Electricity from Swiss hydropower

MEDIPACK – one of the Prix-SVC Award finalists

The sponsor and initiator of the Prix SVC awards is the Swiss Venture Club, an independent association for the promotion and support of SMEs in Switzerland. The Prix SVC Zurich Economic Area Award celebrates outstanding SMEs whose innovative products and services, corporate culture, quality of employees and management, and sustainable track record make them stand out from the crowd. Organisations must be strongly anchored in the region in order to be nominated by the jury.

The award ceremony will take place on 16 January 2020 at the Hallenstadion Zurich.

We are delighted and honoured to have been nominated and would love to come home with the award in January.

Bench Campaign in Schaffhausen - MEDIPACK takes part in it

The MEDIPACK company also took part in the campaign and designed its own MEDIPACK bench. A group of creative and motivated "Medipäcklern" went on a search for ideas and then implemented them artistically - not so easy with so many good ideas.

See for yourself what came out of it. We think our bench is the most beautiful!

From the idea to its success – MEDIPACK was part of it

aspUraclip® is a mini-inhaler for the nose. While inhaling, suitable amounts of the essential oils continuously find their way to the mucous membranes in the nose, helping you to breathe clearly.

The success story had its origins at the Compamed trade fair in Düsseldorf. The inventors of the aspUraclip® were looking for suitable packaging and found it at the MEDIPACK stand. As system supplier we quickly came up with a blister pack for the new product, so the customer obtained everything from one source – including design, film production, tool creation, deep drawing process, right to the production of the sealing lids.

Demand shot up astronomically after the episode was broadcast.

Compamed 2018

For the Sake of the Environment

Sucessful Apprenticeship

We are proud of his achievement and congratulate him on the sucess.

MEDPURPOUCH - Packaging for sharp-edged Products

The material MEDPUR is the particularly suitable solution for packages containing sharp-edged implants, because there is no abrasion if rubbing occurs.

Please find more information HERE.

New Clean Room for Foam Inlays

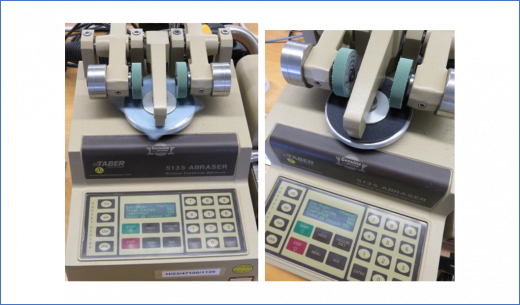

Abrasion tests with the material MEDPUR

Tests show that the material MEDPUR is most qualified for user-friendly packaging for sharp-edged implants like blisters, pouches (MEDPURPOUCH) etc.

40 years of MEDIPACK AG – the success story of a family company

It all started 40 years ago in a small production facility and has since developed into a genuine success story. Today, MEDIPACK AG has a workforce of around 145 employees and delivers high-quality products around the world.

We are particularly proud of our staff. Thanks to their expertise, loyalty and engagement, the company has continued to develop into what we are today – an internationally recognised system supplier of medical packaging.